Water Recovery

Belton Farm employs state-of-the-art processing techniques to recycle water. We recover water from whey using membrane filtration and reverse osmosis, then reuse it for cleaning the membranes.

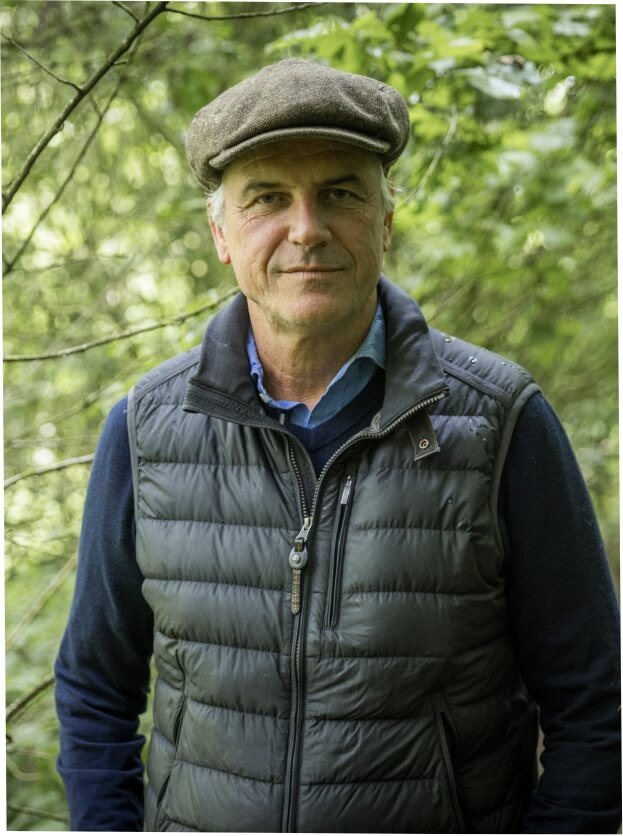

At Belton Farm, we recognise that we must care for and sustain today’s world for future generations.

We value and strive to protect the natural environment and resources that are at the very heart of our business.

Our commitment to achieving Net Zero emissions is based upon an ambitious Carbon Reduction Plan to de-carbonise services across our production including waste, water, energy & on farm.

Sustainable

All the milk used in our award-winning cheese comes from Dairy Farms that are all within a 25-mile radius of the Belton Farm dairy. Our close-knit milk pool reduces our overall transport emissions.

Whey that is produced during the cheesemaking process is another element that we further process to avoid waste, including:

At Belton Farm, we have been monitoring our carbon footprint for cheese manufacturing since 2009. We are committed to reducing the impact of our activities on the environment by optimising our use of resources, minimising emissions, and reducing waste. Central to this has been our rigorous focus on reducing carbon emissions and energy usage through the implementation of various environmental efficiency schemes. As one of the first cheesemakers to introduce a farm-level carbon footprint program in 2013, showing our dedication to sustainability.

We are proud to report since 2009 our greenhouse gas emissions have reduced by 48%, even though our cheese production has grown each year.

In 2023 solar panels at Belton Farm generated 130, 539 kWh, enough electricity to power 3263 electric cars.

We are working closely with our milk producers to advance carbon footprinting initiatives on their farms.

Belton Farm employs state-of-the-art processing techniques to recycle water. We recover water from whey using membrane filtration and reverse osmosis, then reuse it for cleaning the membranes.

Belton Farm is surrounded by beautiful, scenic landscapes, enhanced by the 15,000 trees we planted in 2008 and 600 metres of hedgerows.

Heat recovery units have been implemented at Belton Farm to reduce our reliance on kerosene and gas oil. This has significantly decreased the amount of oil used on site.

General waste is sent to an energy recovery facility, generating green heat and power. Additionally, all our cheese is stored in reusable plastic crates for maturation, significantly reducing cardboard box usage.

Our plans to further reduce greenhouse gas emissions directly and indirectly include:

Continuing farm-level

carbon footprint assessments.

Expanding our solar panel installations

to generate more on-site electricity.

The field mounted solar panels went live in April 2025, producing up to 2.5 MW, providing a further 40% of our electricity. Covering an area of 2.53 hectares, the solar farm will generate an estimated 2100MWh’s of renewable energy annually. This energy will then be consumed by Belton Farm, helping us to move closer to our goal of becoming self-sufficient in energy usage. Here’s to a greener future.

Optimising energy usage for the manufacturing operations.